plc

The PLC is:

PLC is the abbreviation for PROGRAMMABLE LOGIC CONTROLLER, meaning programmable logic controller, a device developed to replace traditional electrical control that uses timers, reels, contractors, counters, etc., for control of industrial machines and machines, for example, packaging machines in factories.

PLC, what is PLC

The PLC device looks at the inputs and is INPUT and depending on the condition ON / OFF 0/1 and through the program within the PLC controls the output OUTPUT See figure.

The user usually enters the program using a program for the PLC device used but ultimately doing the same work required.

PLCs are very much used in the working life, where there is a PLC industry in the industry.

To illustrate the picture, we all know the light signals. In order to control one light signal, on the assumption that the signal is red and then yellow and then green to control, we need three times to do so.

But what if we wanted to control a four-way fork? Do you imagine how much time we need to control it, so the more control you see, the more PLC you need.

Features of PLC

small size.

Ease and speed in making changes to the control system

Integrated control and fault detection system

Immediate and continuous monitoring and documentation system.

Low cost.

(Logic 0, Logic 1) Logic 0, Logic 1

PLC can only understand the digital signal that is either ON or OFF. Binary System is the system with only two numbers (1 and 0). The binary number 1 indicates that the signal is present or that the key is in the mode ON and the binary number 0 indicates that the signal does not exist or that the key is in Off mode

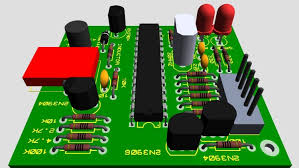

PLC is a group of electronic circuits combined in the form of modules specialized in the work of real-time control Real Time System and through which control and control of the processes that are implemented

The PLC performs a set of instructions stored in its memory in the form of a program and is therefore very similar to computers or computer, but there are differences that we will explain in the following:

PLC can be connected directly to sensors and devices through the input and output units, especially the industrial.

PLC is designed to work in industrial environments, including harsh conditions of high temperature, dust, vibration and distortion of voltage and current waves, low and high voltage and current.

PLC programming languages are designed in a way that does not require advance knowledge in computer languages or to a high level of programming and written in known ways, most notably the Ladder & STL

Components of the PLC unit

The PLC unit consists of the following main components:

Input Module

CPU

Output module

Power supply unit

Operator unit

Programming Device Programming Device

Components of the PLC unit

Input Module

- The input unit is connected to a set of physical elements such as switches, sensors, thermometers, weight and fluid level sensors, etc. The input unit receives the analogue and digital signals sent from these elements and converts them to logical signals that can be handled by the processing unit Central.

CPU microprocessor CPU

It is a microprocessor that contains system memory and is also the decision-making center of the PLC unit and does the following:

Receiving and processing logical signals sent from the input unit

Make appropriate decisions according to the instructions stored in the program memory.

Issue control commands to the output unit according to program instructions stored in memory.

- The CPU unit performs a number of operations such as counting, timing, data comparison, serial operations and displacement.

Move the program's help stored in memory

Memory module

There are two main types of memory in the PLC unit:

1 - Random memory (RAM) is the memory that can enter data (data) directly from any address (Address) and can write and read data from this memory. This means that the data stored in it will be lost if the power is lost. Therefore, a battery is installed to avoid data loss if the main power is lost.

2 - ROM is the memory from which the data can be read but can not write data in it. This memory is used to protect the data or software stored in it from erasure, which is permanent memory and this means that the data stored in it will not lose in case of loss of electricity.

This memory is divided into:

Programmable Read and Programmable Memory (EPROM) is read-only memory, but data can be erased by exposing it to ultraviolet light and ready to receive new data with its own data writer.

(EEPROM) is read-only, but the data stored in it can be erased by setting it to Unprotected Mode and then entering new data.

Memory plc

Output Module

The output module performs the following functions: Receiving the logical control instructions sent from the CPU and converting them to digital or analogue signals that can be used to control a variety of devices Actuators,

CPU and converted to digital signals

Different models of PLC:

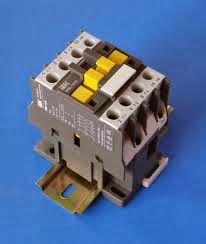

Smart relays SR1

Zelio Logic SR2-SR3 compact smart relay

PLC programming:

There are several languages used to program the PLC device and among the common programming languages:

Program of the peaceful scheme Ladder diagram:

It is one of the most widely used languages