PLC Basics

What is PLC?

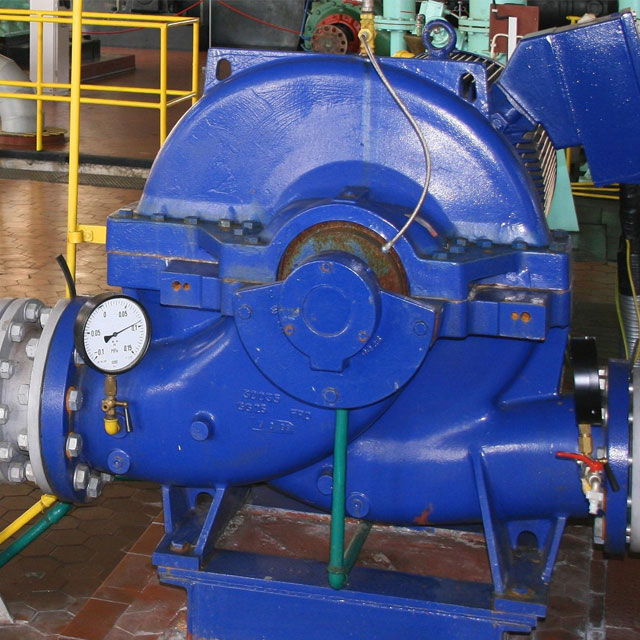

Programmable Logic Controller, or PLC, is simply a special computer used for industrial control systems. It is used in many industries such as oil refineries, manufacturing lines, transport systems and so on. Whenever there is a need for hardware control, PLC provides a flexible way to "ease" the components together.

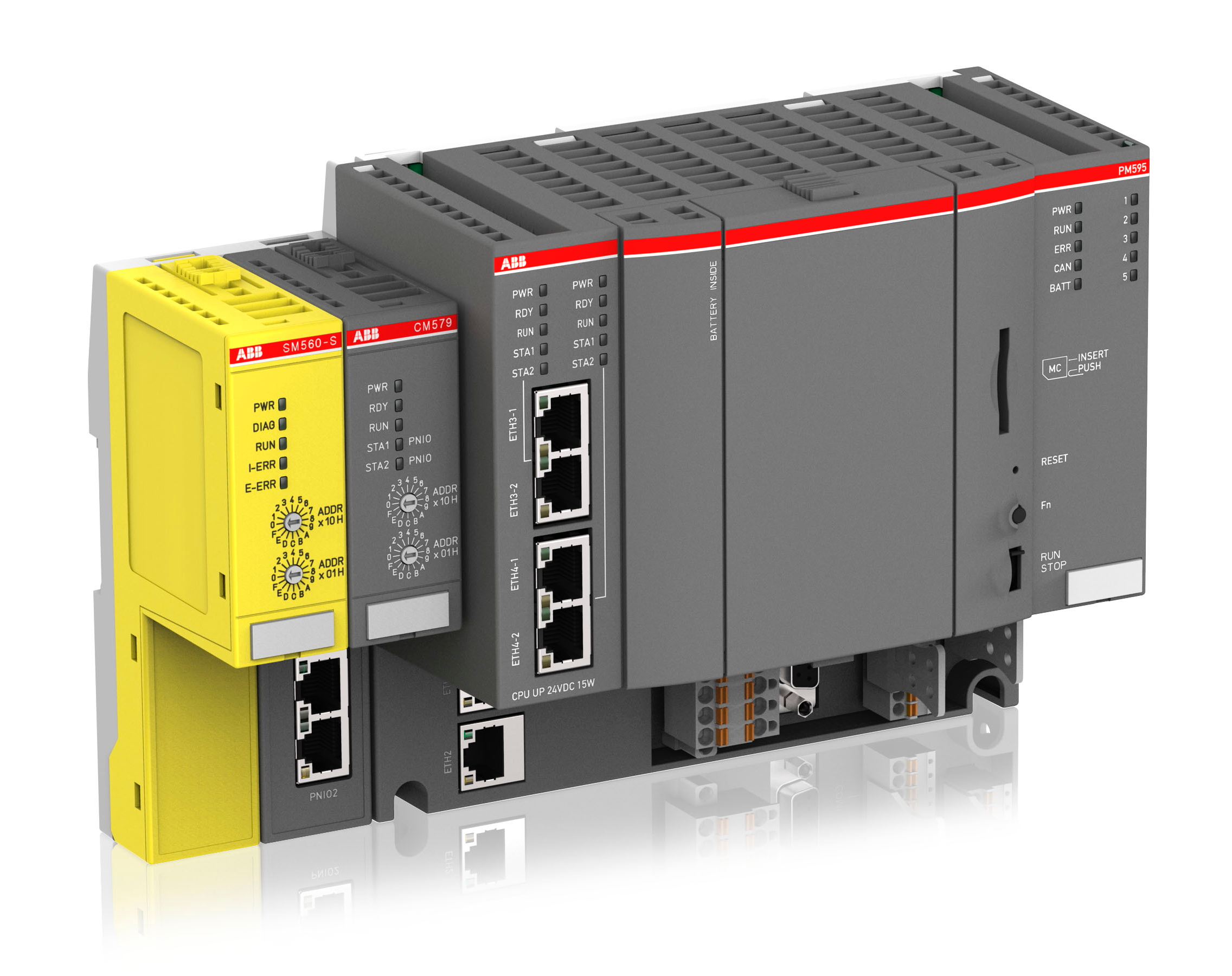

Core modules contain a dedicated CPU to run a single program that monitors a series of different inputs and processes the output to the logical control. It is intended to be very flexible in how these programs are programmed with high reliability (no program failure or mechanical failure), integrated and economical control systems on traditional control systems

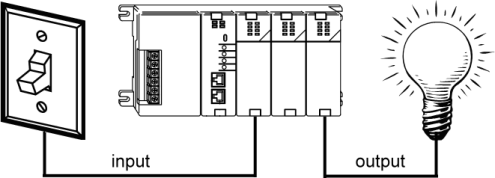

How PLCs work

A programmable logic controller is a specialized computer used to control machines and processes. So they share common terms with normal computers such as CPU, memory, software and communications. Unlike the PC despite PLC design to survive in a rugged industrial environment and to be very flexible in how it interacts with inputs and outputs to the real world.

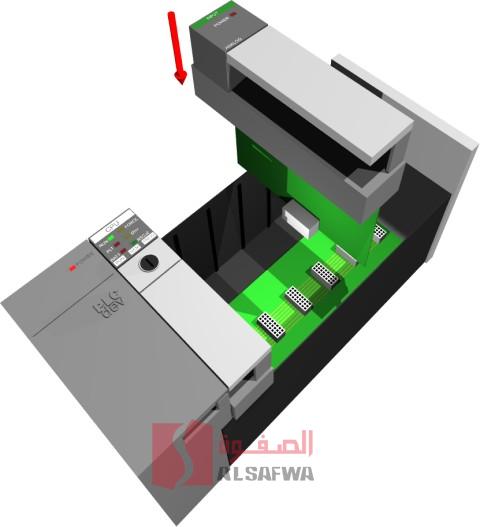

Components that make PLC work can be divided into three main areas.

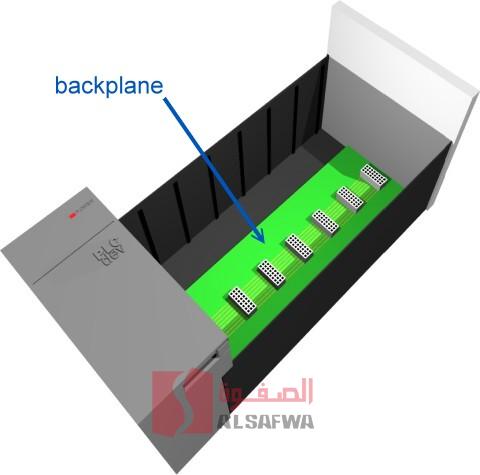

Power supply and rack

CPU

Input / Output (I / O)

PLCs come in many shapes and sizes. It can be quite small so fit your shirt pocket while the most widely used control systems require large PLC racks. Smaller PLCs (nicknamed "bricks") are usually designed with fixed I / O points. For its consideration, we will consider systems based on more modular units. It is called "modular" because the rack can accept many different types of I / O modules that simply slide to the shelf and connect it.

Apply Now

you can apply now and we willl contact Yiu Soon