PLC Advanced

Course contents

PLC programming

Correct and correct programs that do not work.

Learn how to reduce multiple degrees of one ladder.

Learn how to measure multiple analog inputs using a single degree.

Create programs that depend on the specifications presented to you in the chapter.

Learn TABLE and POINTER comands and use them.

Learn the functions and programs of C-More Panels.

Wire, Program, Terminator Usage and 205 I / O Distance.

Type "organized" programs using phase programming.

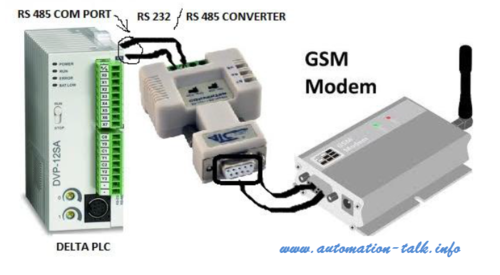

Debugging, diagnosing and programming PLCs over cellular phones.

Write a program to control the automatic welding model on the network.

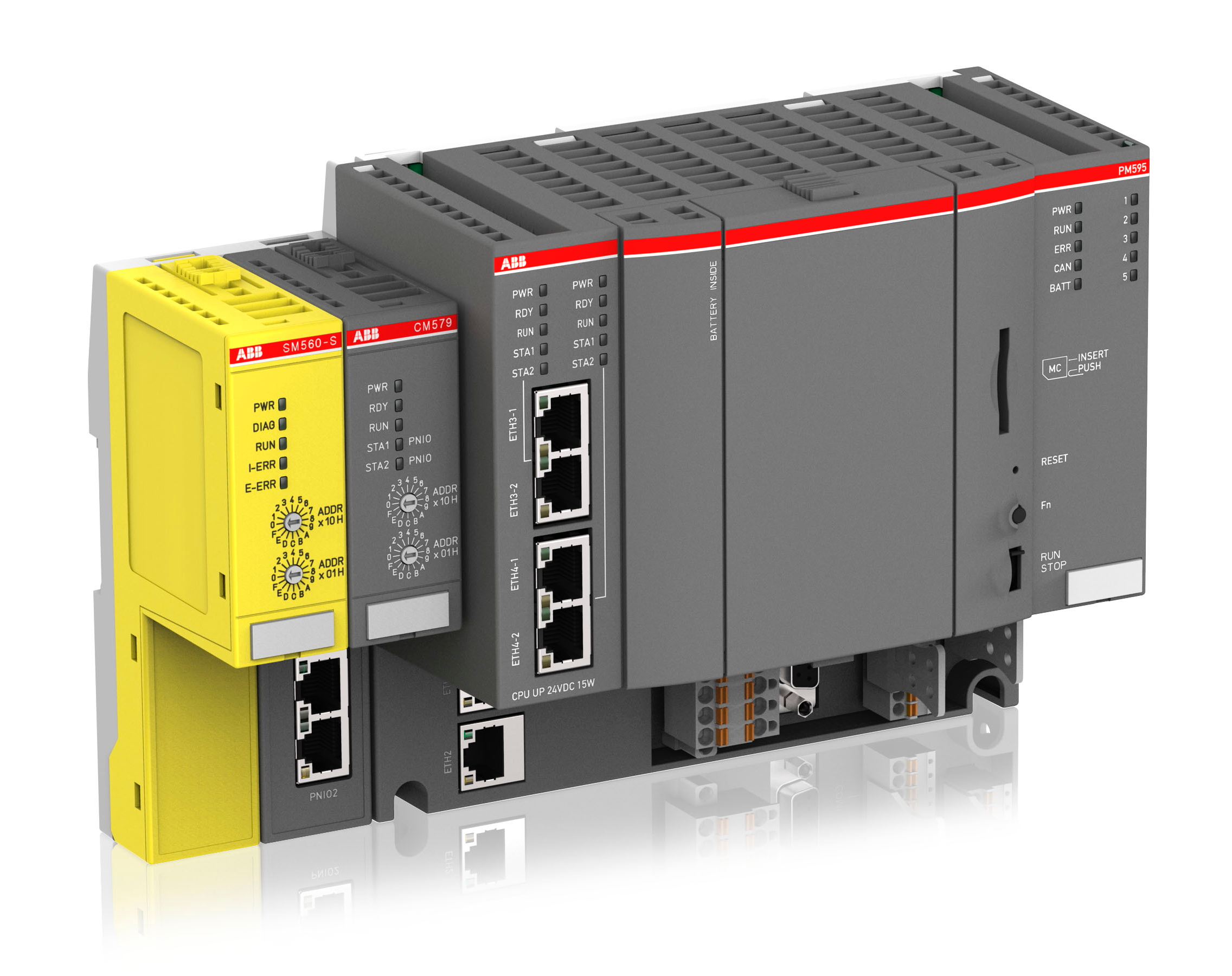

Networks

Serial RS-232 and RS-422

Ethernet - wired, wireless, fiber optic, MAC, IP, PLC, addressing

Learn how to use photoeyes software, converge keys and cryptographic programs.

Networks with multiple PLs and PLC master / slave.

Learn how to connect a PLC network and write the program using the support commands to read and write on the network.

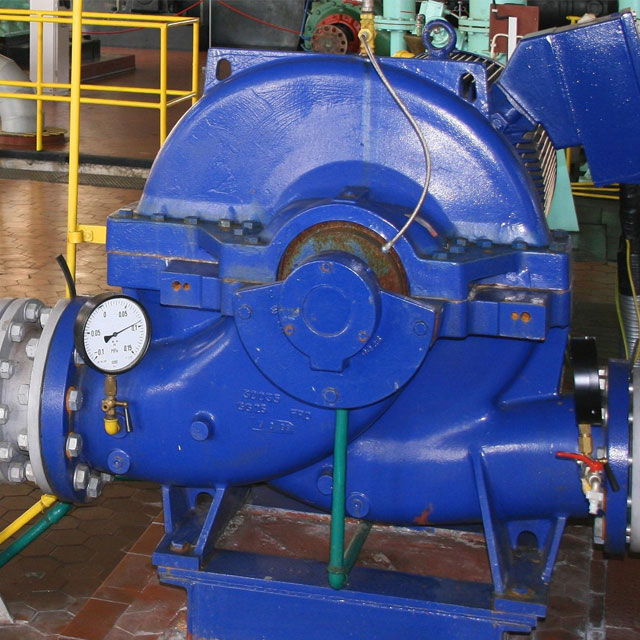

Read the engine speed (from the encoder installed on the drive to the high speed counter input) and display on the remote PLC

Control the engine speed from a master PLC to a slave with engine setup / encryption.

View the speed of your engine on the training systems throughout the room.

Apply Now

you can apply now and we willl contact Yiu Soon